Furnace Refractory and Mechanical Repair

Furnace Rebuilders Incorporated > Furnace Refractory and Mechanical Repair

Furnace Refractory and Mechanical Repair

Refractory Installations

Trust us to handle your refractory installation needs with utmost professionalism and cost-effectiveness. Contact us today to discuss your project and receive a personalized quote.

Why Choose Us?

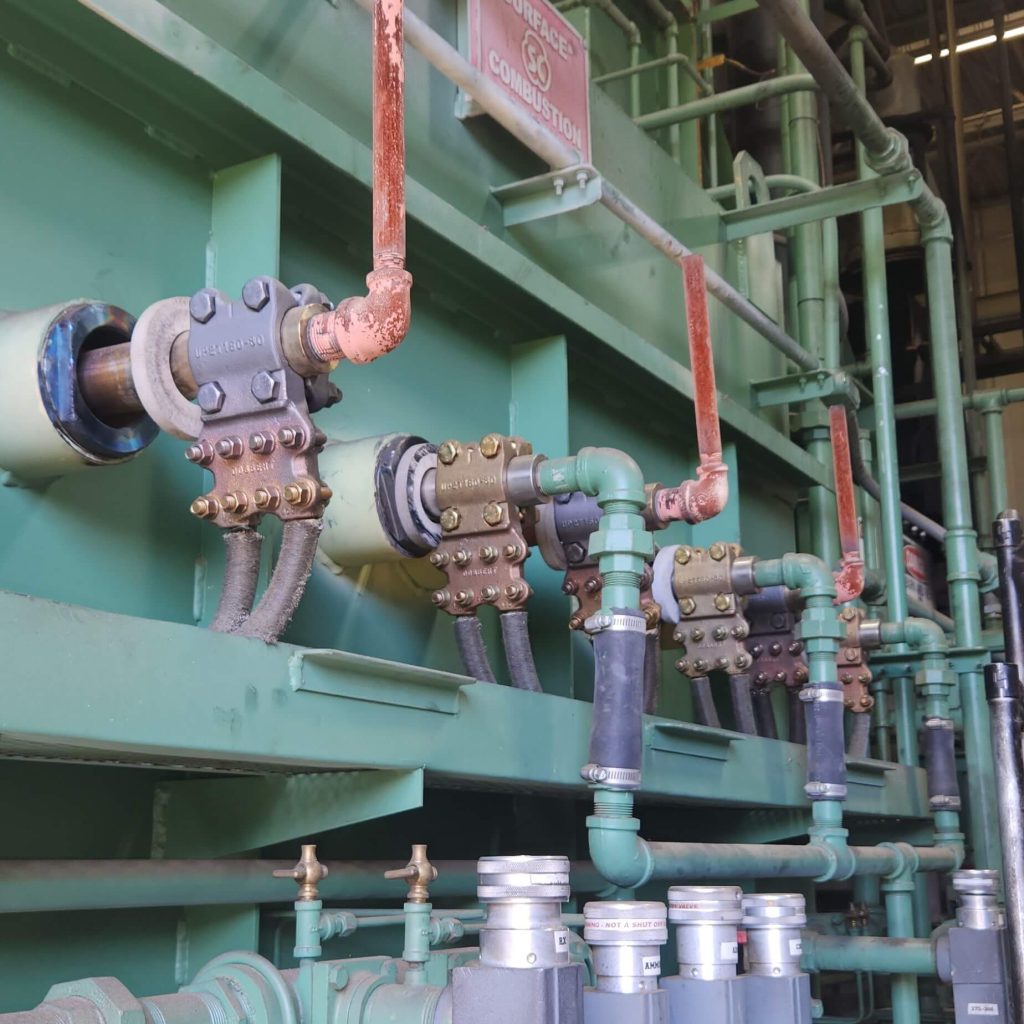

Our process starts with a thorough inspection of your equipment, allowing us to provide tailored recommendations.

When it comes to the actual installation, we only work with top-quality materials, ensuring durability and longevity. Our team of experienced technicians specializes in this specific type of equipment and construction, guaranteeing a professional and flawless installation.

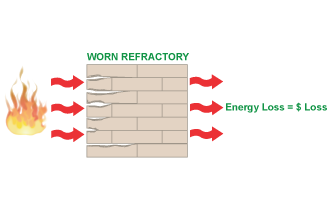

Conserve Energy and Lower Operating Cost

Thermal expansion and contraction of heat-treating equipment (furnaces, ovens, kilns) causes wear and tear on refractory linings which creates deterioration and loss of costly energy. Repair or replace refractories, doors, and seals. It Pays!

Safety Comes First

Our employees meet or exceed OSHA guidelines in safety training. Service technicians maintain annual OSHA 10-hour training in areas specific to heat treating. We have the ability to build containments when requested by our business partners that maintain a dust-free environment while the work is being completed. These enclosures prevent dust and other particles from contaminating the surrounding shop area.

Preventative Maintenance

Many times, production demands become a priority over maintenance. Unexpected downtime on mechanical equipment which is not properly maintained is inevitable. However, it may be avoided with a comprehensive preventative maintenance program. Many of our customers have proven that scheduled downtime for proper maintenance is less costly than running equipment until failure. Our programs are tailored to the specific type and operation of each furnace.