Leading Rebuilder of Industrial Heat Treating Furnace Equipment

Years Experience

Companies Serviced

Total Jobs

Well Maintained

Industrial Specialist

Latest Equipmets

Safety Commitment

About Industry

- Leading industrial solutions with best machinery

- Years of experience and Learning

- Experienced specialist researchers.

- Reputed for maintaining Schedule

- Latest of the Equipments

- Committed for the safety of the customers

Daniel Ricardo

Services

For Industries

Furnace Refractory and Mechanical Repair

Pyrometry, Controls and Heating Systems

Parts, Material Supply and Shop Services

Safety and Environmental

Services For Industries

Furnace Refractory and Mechanical Repair

Pyrometry, Controls and Combustion Systems

Parts and Materials Supply

Our Services

Furnace Refractory and Mechanical Repair

Pyrometry, Controls and Heating Systems

Parts and Materials Supply

Get a Free Quote for Your Industrial Project

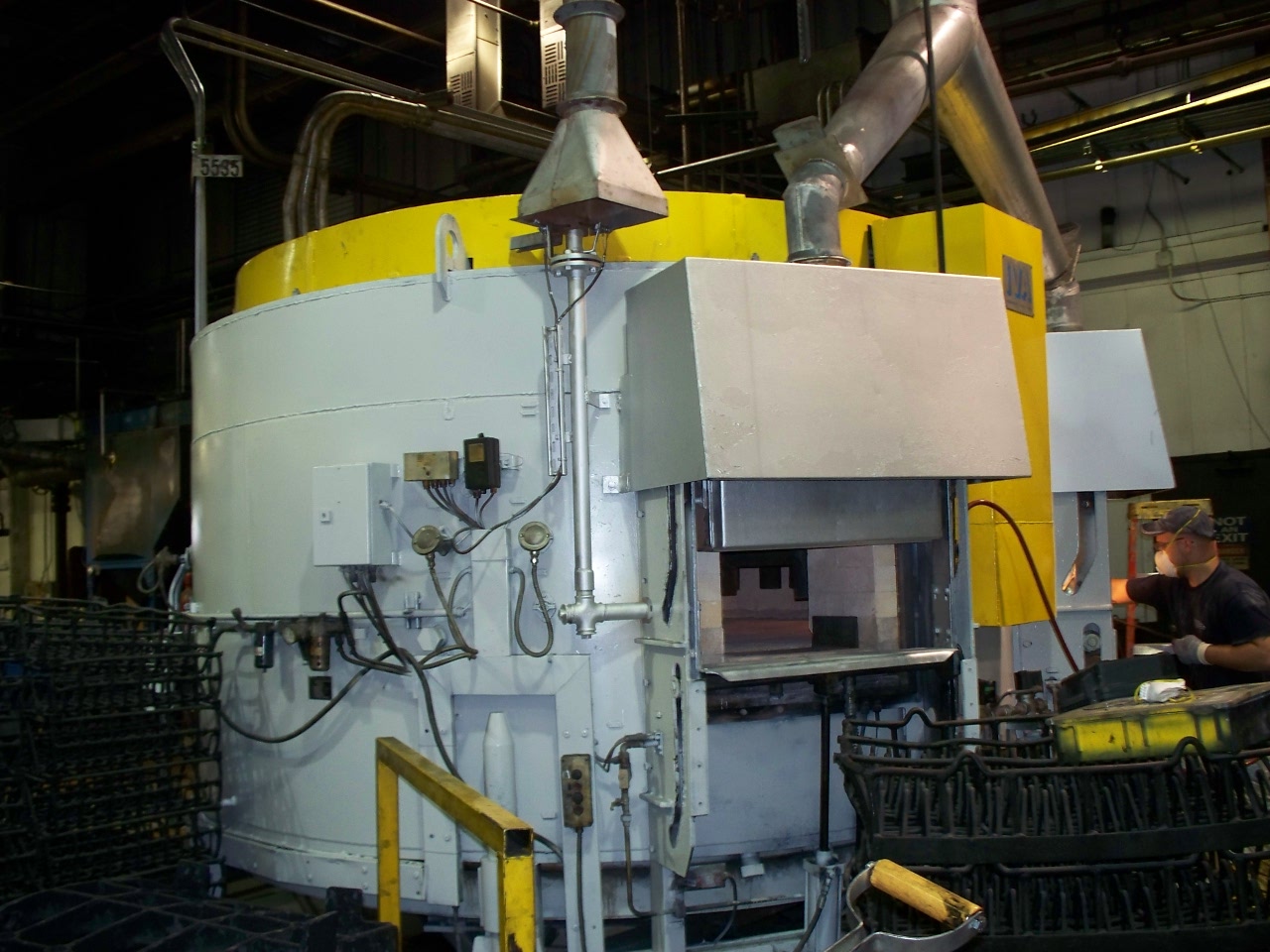

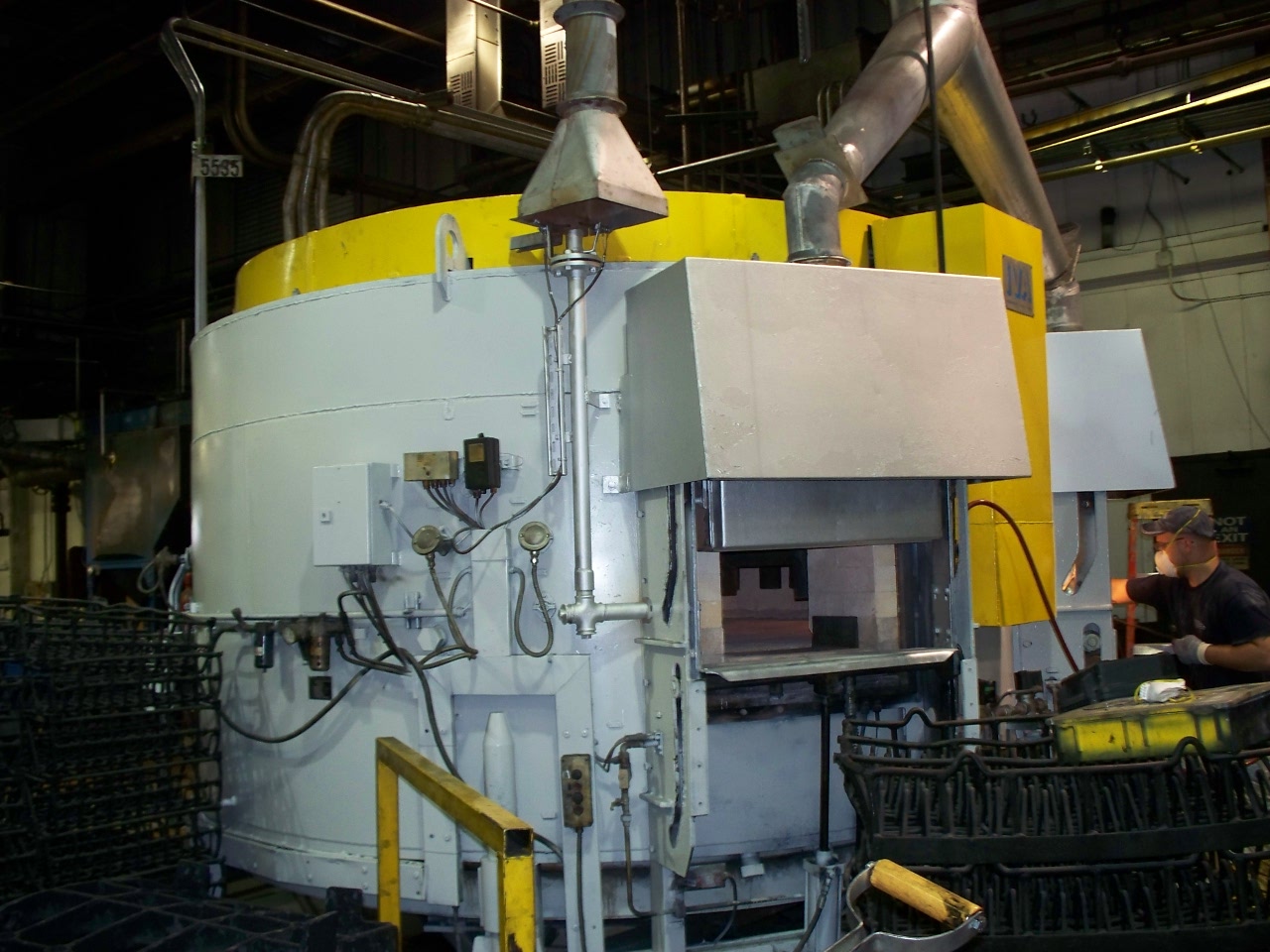

Recent Projects

Roller Hearth Furnace Reline and Heating Element Upgrade

Experience a significant improvement in element life and maintenance with our Roller Hearth Furnace Reline service. We transformed a 50-foot furnace by replacing heating elements mounted directly on the brick face with a state-of-the-art solution: heating elements mounted in radiant tubes, coupled with a complete furnace rebricking. Say goodbye to frequent heating element repairs and embrace enhanced reliability and efficiency for your large roller hearth furnace.

Skid Rail Conversion

Converting from failing skid hearth tiles to precast silicon carbide skid rails. Designed to withstand thermal shock, these silicon carbide rails offer enhanced durability and reliability, especially during load entry when furnace doors are open. Say goodbye to skid hearth tile issues with our innovative skid rail conversion.

Client’s Reviews

James Shane Well

James Shane Well